Medical implant devices are a high-risk product group because their materials remain in long-term contact with living tissue, bodily fluids, and blood. Therefore, rubber used for implants must meet stringent requirements for biocompatibility, long-term stability, and control of extractables and leachables. In this article, Thai Duong Plastics compiles key technical requirements and important standards to..

In an automotive braking system, rubber parts may be small, but they play a critical role in ensuring sealing integrity, pressure stability, and long-term durability. As modern vehicles demand higher levels of safety, service life, and performance under harsh operating conditions, rubber materials used in brake systems must be selected more carefully. In this article,..

In food processing and packaging lines, accessories such as gaskets, seals, washers, flexible hoses, plugs, diaphragms, and similar components are often direct contact points with the product. Choosing the wrong rubber material can cause odor, chemical migration (leaching), rapid aging during CIP cleaning, leakage, and other issues-ultimately increasing food-safety risks. In this article, Thai Duong..

In rubber manufacturing, airborne particulate contamination directly affects visual appearance, surface cleanliness, and the packaging quality of finished goods. ISO Class 8 cleanrooms-equivalent to Class 100,000-are widely adopted by many factories as a baseline environmental control solution for specific production steps. Drawing on experience implementing cleanroom setups for technical rubber lines, Thai Duong Plastics shares..

China is the world’s largest consumer of rubber and one of the most important import hubs for natural rubber. As industrial production continues to expand, the country relies heavily on raw material supplies from other Asian nations. Fluctuations in China’s rubber industry not only affect its domestic market but also directly influence the trade balance..

Is working in a plastics company hazardous, and what should you do to protect your health? In this article, Thai Duong Plastics helps you better understand the working environment in the plastics industry, potential risks, and essential protective measures. Table of Contents How hazardous is the working environment in a plastics company? The level of..

Overmolding is an advanced injection molding technology that combines rigid and soft materials within a single manufacturing workflow to produce parts with high durability, strong aesthetics, and optimized functionality. In the article below, Thai Duong Plastics will help you clearly understand the concept, process, material selection, and industrial applications of overmolding. Table of Contents What..

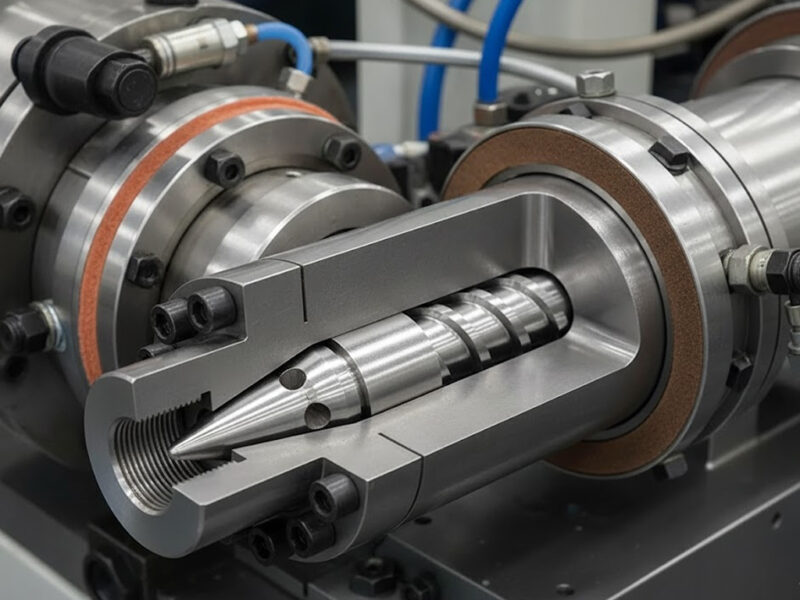

The screw in an injection molding machine is the key component responsible for heating, compressing, and pushing molten plastic into the mold. Understanding the screw’s structure and operating principle helps operators optimize the injection molding process, ensure product quality, and extend equipment service life. In this article, Thai Duong Plastics shares detailed information on the..

Extrusion blow molding is one of the most important technologies for manufacturing packaging and hollow plastic products. Thanks to its precise forming capability, reasonable cost, and high production speed, this technology is increasingly applied across consumer goods, food, pharmaceuticals, and chemicals. In this article, Thai Duong Plastics will help you understand the fundamentals, operating process,..

Mold tooling is the foundation of modern manufacturing, playing a critical role in shaping products across most industrial sectors. In this article, we will take a closer look at what a mold is, the production workflow, and the advanced technologies commonly used in mold machining today. Table of Contents Overview of Mold Tooling A mold..

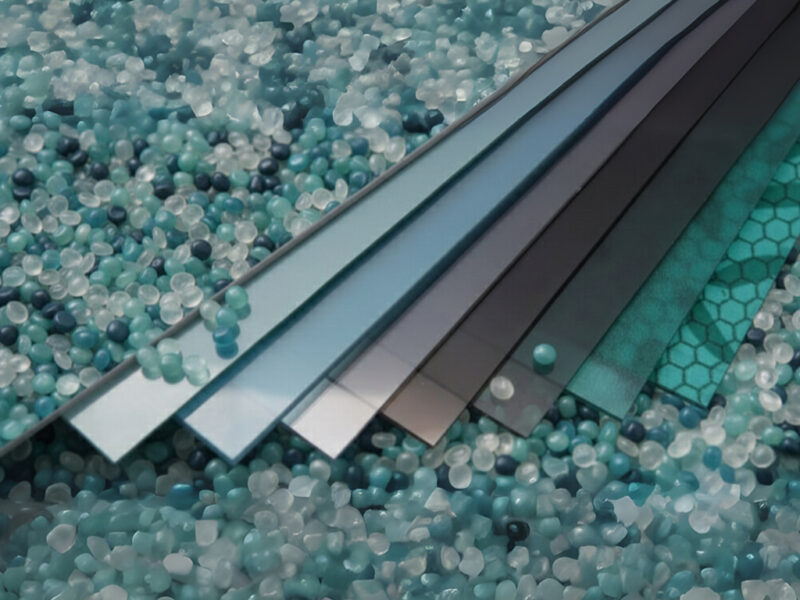

Plastics are commonly classified based on three main criteria: thermal behavior, feedstock origin, and the Resin Identification Code (RIC). In this article, Thai Duong Plastics will help you better understand key characteristics, applications, and how to choose the most suitable plastic for your needs. Table of Contents Classifying Plastics by Thermal Behavior This is the..

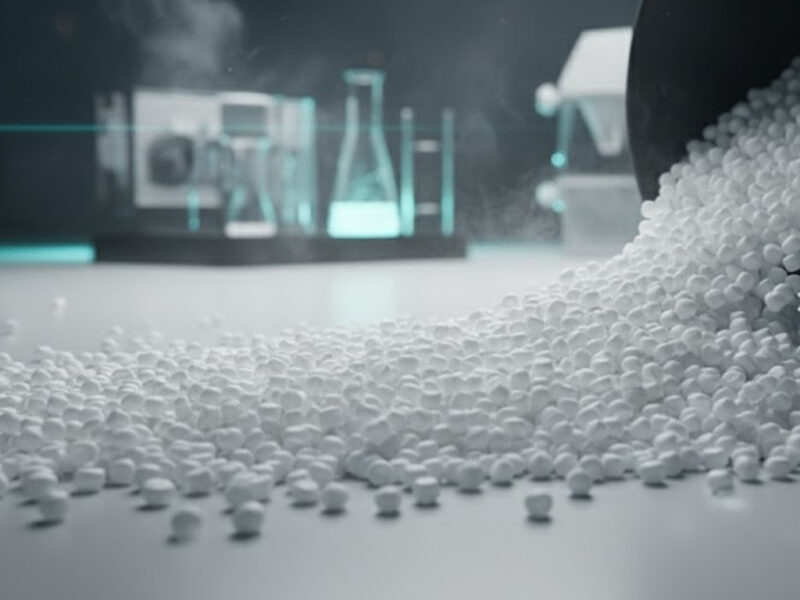

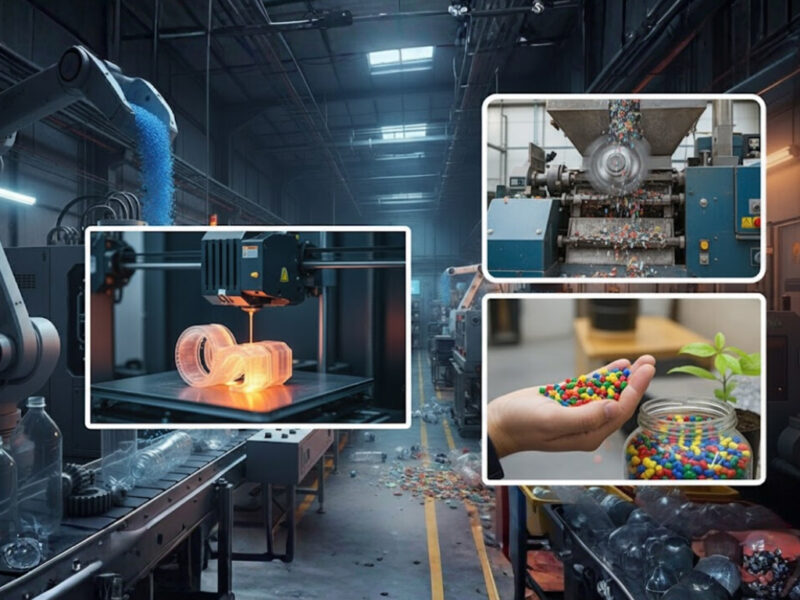

Plastic recycling has become an inevitable trend as waste pollution grows increasingly severe and fossil resources gradually decline. This activity not only helps protect the environment but also provides an important material source for modern manufacturing. In the article below, Thai Duong Plastics will help you clearly understand what plastic recycling is, how the process..

Plastics play an important role and are among the most widely used materials in most manufacturing and everyday applications. Not only because they are affordable, plastics also offer outstanding characteristics such as being lightweight, durable, flexible, and easy to shape. To better understand this material, join Thai Duong Plastics as we explore the article below…

Plastics are widely used across most manufacturing sectors and daily life-such as packaging, engineering components, and electronic devices-thanks to their durability, light weight, and ease of forming. Understanding the properties of plastics helps businesses select the right materials, optimize processing, and produce higher-quality products. In the article below, Thai Duong Plastics will provide an in-depth..

Synthetic plastics have transformed the way people design and manufacture products across many areas of everyday life and industry. In the article below, Thai Duong Plastics will help you better understand the concept, characteristics, classifications, and practical applications of this type of plastic. Table of Contents What is synthetic plastic? Synthetic plastic is a man-made..

Bioplastics are becoming a new material trend in modern industry thanks to their environmental friendliness and potential to replace conventional plastics. As awareness of plastic pollution continues to grow, it is essential to understand the characteristics and role of this material in sustainable development. In the article below, Thai Duong Plastics will give you the..

Recycled plastics are becoming an inevitable trend as plastic waste pollution continues to increase. Reusing this source of material helps conserve resources and contributes to reducing emissions that pollute the environment. In the article below, Thai Duong Plastics will help you clearly understand what recycled plastic is and the characteristics of the seven most common..

Accurately distinguishing different types of plastics helps consumers use them safely, enables businesses to choose appropriate materials, and improves recycling efficiency across society. With many years of experience in plastic manufacturing and plastic processing, Thai Duong Plastics shares this detailed guide to help you identify, understand the origin and properties of, and correctly use the..

Plastics manufacturing is an industry that synthesizes polymers from petrochemical feedstocks or recycles post-consumer/industrial plastic waste to produce virgin and recycled pellets, then shapes them into finished parts using advanced processing technologies. It is a foundational industry that supplies essential materials to nearly every sector. Follow the article below from Thai Duong Plastics to explore..

Tritan plastic has become a familiar material in many household products today. Thanks to its glasslike clarity, durability, and good heat resistance, Tritan is gradually replacing many traditional plastics. Still, many people wonder whether Tritan is truly safe and how it differs from other plastics. In this article, Thai Duong Plastics takes a closer look..

PPSU plastic has been gaining popularity in the production of premium products thanks to its heat resistance, outstanding durability, and high level of safety. Still, many people wonder what PPSU actually is and whether it is truly good for human health. In this article, Thai Duong Plastics will explain the properties, advantages and disadvantages, and..

PA6 plastic, also called Nylon 6 in the polyamide family, is a widely used engineering thermoplastic thanks to its high mechanical strength, good wear resistance, stable heat performance, and effective electrical insulation. In the article below, Thai Duong Plastics provides an overview of PA6-its structure, properties, processing parameters, and real-world applications. Table of Contents Detailed..

TPV plastic-short for thermoplastic vulcanizate-is widely used thanks to its flexible processing, outstanding mechanical and chemical performance, and recyclability. In this article, Thai Duong Plastics will help you understand TPV’s composition, properties, and key applications in today’s manufacturing. Table of Contents About TPV (Thermoplastic Vulcanizate) TPV stands for Thermoplastic Vulcanizate and belongs to the TPE..

TPR plastic is now widely used across many industries thanks to its ability to combine the elasticity of rubber with the processability of thermoplastics. It is a tough, flexible, safe, and environmentally friendly material. Thai Duong Plastics provides detailed information about TPR and compares it with other common elastomeric plastics. Table of Contents What Is..

Polycarbonate (PC) is one of today’s most important engineering plastics. It offers light transmission close to glass, excellent impact resistance, and strong dimensional stability, making it highly popular. In the article below, Thai Duong Plastics provides comprehensive information about PC to help you evaluate, select materials, and design for efficient manufacturing. Table of Contents Key..

TPU plastic is widely used across industry and consumer products. It is increasingly favored for its flexible combination of durability, elasticity, and robust resistance. So what exactly is TPU, what standout properties does it have, and how is it used? Join Thai Duong Plastics for a detailed look below. Table of Contents What Is TPU..

TPE (thermoplastic elastomer), also called thermoplastic rubber, stands out for its flexibility, safety, and recyclability. This material has been replacing many conventional plastics by meeting both performance requirements and environmental goals. In this article, Thai Duong Plastics will help you understand TPE more clearly so businesses and users can choose the right material for each..

Thermoplastics are among the most widely used materials in industrial manufacturing, appearing in everything from packaging and electronic components to building materials and high-precision parts. In the article below, Thai Duong Plastics will help you understand what thermoplastics are, their properties, examples, and applications in plastic processing. Table of Contents What are thermoplastics? Thermoplastics are..

Thermosetting plastics are an important class of polymers that play a pivotal role in the plastics industry and many high-tech engineering fields. Thanks to their permanent curing behavior and outstanding heat resistance, thermosets are used wherever high mechanical strength and long-term stability are required. However, they also have certain limitations that should be weighed carefully..

PU plastic is a family of polymers formed by the reaction between an isocyanate and a polyol to create carbamate linkages (also called urethane linkages). This material spans a wide property range from soft to hard, noted for excellent abrasion resistance, high elasticity, strong adhesion to metals, chemical resistance, and stable electrical insulation across common..

PE (Polyethylene) is one of the most widely used thermoplastics in the world thanks to its flexibility, durability, moisture resistance, and low cost. Still, many people wonder whether PE is safe or potentially harmful when used for food contact and everyday household items. In the article below, Thai Duong Plastics explains PE in detail-its applications,..

LDPE (Low Density Polyethylene) is one of the most widely used thermoplastics today thanks to its flexibility, light weight, and safety for food contact. Like many other plastics, however, LDPE has its own strengths and limitations and should be used correctly to ensure safety and environmental sustainability. Join Thai Duong Plastics in the article below..

HDPE (High Density Polyethylene) is a thermoplastic widely used in industrial production and everyday life thanks to its high strength and versatility. So, is this material truly safe to use? How heat-resistant and insulating is HDPE? Follow the article below from Thai Duong Plastics for the details. Table of Contents Overview of HDPE Plastic HDPE..

Pressure forming is one of the most important technologies in today’s plastics manufacturing. This technique uses compressed air to press a heated plastic sheet against a mold, producing parts with greater detail and accuracy than many other forming methods. Join Thai Duong Plastics to learn why this technology is widely applied across manufacturing sectors. Table..

Rotational molding (also called rotational moulding or rotomolding) is a plastics-processing technology that is less common than injection or blow molding. It is an optimal process for large, hollow products that require high mechanical strength. In this article, Thai Duong Plastics explains what rotomolding is and how it differs from thermoforming, helping you choose the..

Extrusion is a material-processing technology widely used across many industries. At its core, the method forces molten material through a shaping die to create products with the desired cross-section and form. In the article below, Thái Dương Plastics will help you understand this technology within the scope of plastic extrusion. Table of Contents What is..

Blow molding is one of the most important technologies in plastics processing, widely used to produce hollow products such as bottles, jars, jerrycans, and tanks. In the article below, Thái Dương Plastics explains key technical features, the manufacturing process, and how to choose the right blow-molding method for each product. Table of Contents What is..

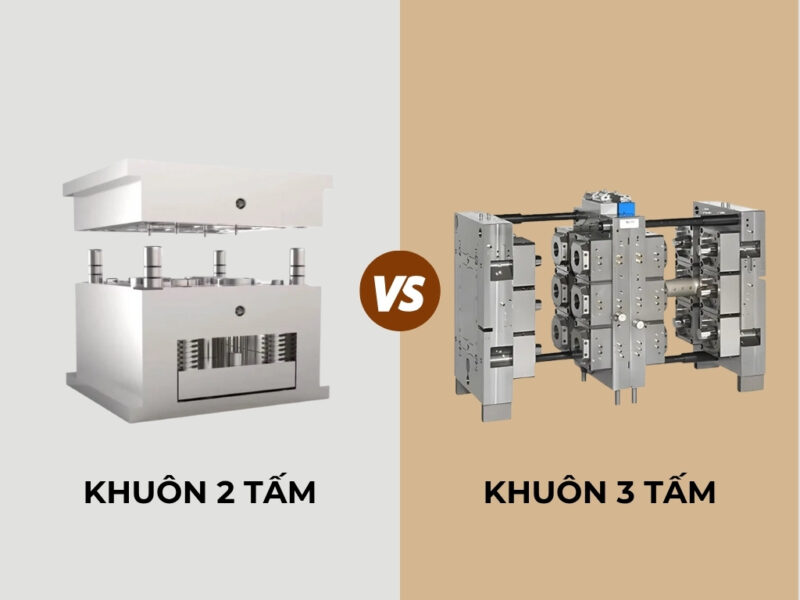

Molds play a decisive role in product quality and productivity in industrial injection molding. Among them, two-plate and three-plate injection molds are the two most widely used types. Although both are used to shape plastic parts, differences in design and operation mean each type suits different production needs. Table of Contents Structural Differences Between Two-Plate..

Hydraulic injection molding machines are widely used thanks to their strong clamping force, robust build, and ability to produce large plastic parts. They are common in industries such as automotive, pallets, trash bins, and industrial packaging. In this article, Thai Duong Plastics introduces this machine type in detail and suggests six brands trusted by many..

Vietnam’s rubber industry has long been a pillar among key agricultural exports while also making a major contribution to the processing sector. In 2024, the industry recorded a historic high in export value, laying a positive foundation for the next stage of development. Amid tightening global supply and rising demand from major downstream industries, Vietnam’s..

Household plastic products are increasingly popular thanks to their convenience, durability, light weight, and reasonable prices. The growing demand for bespoke designs has driven rapid development of plastic processing services for household goods. This solution helps businesses and individuals obtain products that fit their needs while meeting quality standards and aesthetic requirements. Table of Contents..

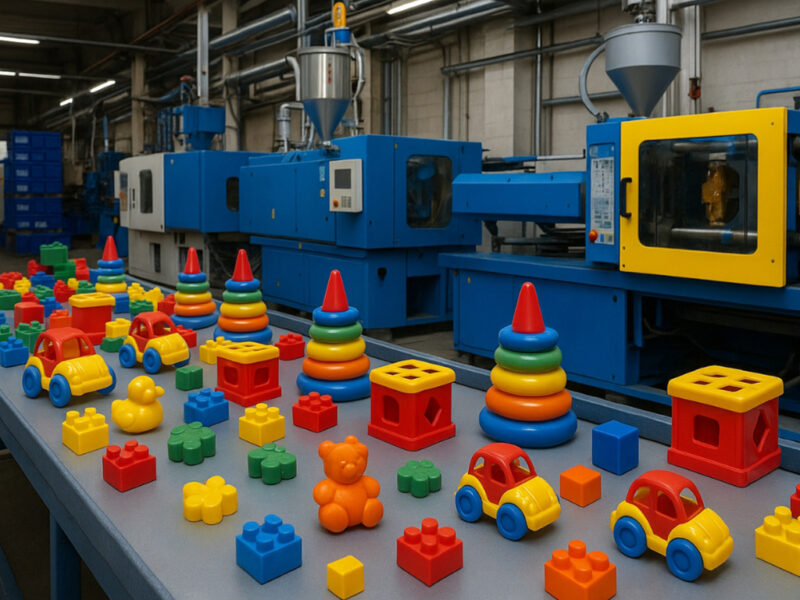

Plastic toys consistently rank among the best-selling product categories thanks to their diverse designs, reasonable prices, and ability to be mass-produced. To ensure consistent quality and on-time delivery, many businesses choose to partner with contract manufacturers rather than investing in machinery themselves. In this article, Thai Duong Plastics shares information about materials, technologies, and quality-control..

The pet accessories market in Vietnam and many neighboring countries is growing rapidly. Toys for dogs and cats not only keep pets entertained but also help reduce stress, improve behavior, and strengthen the bond with their owners. Among these, plastic toys are favored for their durability, affordability, and design flexibility. Seizing this trend, Thai Duong..

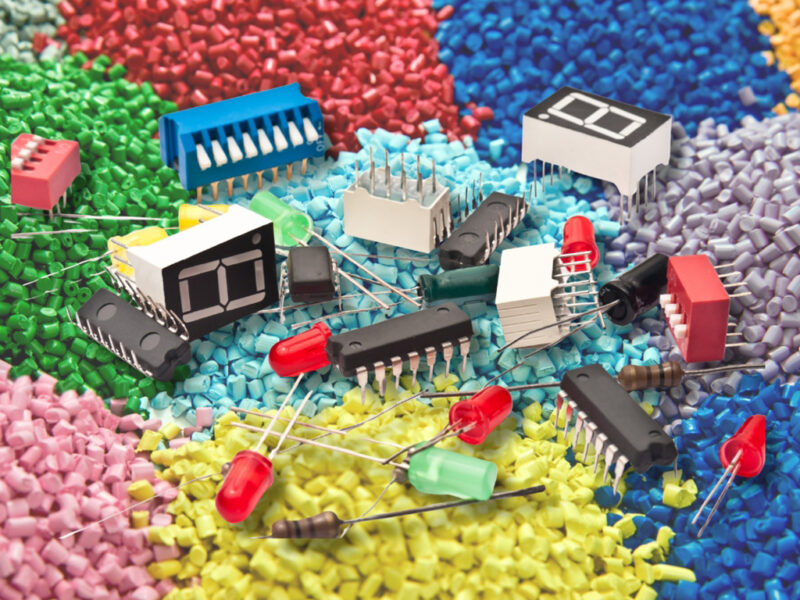

Plastic component manufacturing is the process of producing plastic parts according to technical drawings, serving a wide range of industries such as mechanical engineering, electronics, automotive, and healthcare. With advantages in light weight, durability, formability, and cost-effectiveness, plastics are increasingly used to replace metals in many applications. This process demands modern technology and high precision..

Automotive plastic component manufacturing is the process of producing parts in plastic according to technical drawings or specific use requirements. These parts help reduce vehicle weight and save fuel while still ensuring durability, safety, and aesthetics. This is a key solution in the modern automotive industry. Table of Contents The role of plastic components and..

Medical plastics manufacturing is the service of producing components-such as syringes, trays, device housings, and surgical accessories-by injecting molten plastic into molds with high precision. This process uses biocompatible materials that withstand sterilization and comply with international safety standards, helping businesses control costs, shorten time to market, and ensure clinical performance. Table of Contents The..

A plastic injection molding machine is a critical asset in modern manufacturing, enabling high-precision plastic parts to be made in short cycle times. To maximize effectiveness, manufacturers should understand the construction and the role of each assembly. In this article, Thai Duong Plastics analyzes the main components of an injection molding machine and the technical..

The plastic injection molding process is one of the most important manufacturing techniques in today’s plastics industry. This technology enables the production of complex shapes, small details, high dimensional accuracy, and stable quality. By melting plastic pellets, injecting the melt into a mold under high pressure, and maintaining key parameters throughout the cycle, injection molding..

Medical rubber tubing is an indispensable component of modern medical supply systems. This tubing is primarily made from medical-grade silicone rubber that meets stringent biocompatibility requirements. Join Thai Duong Plastics to learn more about this product and why it is so widely used in hospitals and clinics. Table of Contents Essential information about medical rubber..

Amid rising demand for medical gloves to protect health and workplace safety, finding reputable manufacturers that meet international standards is essential. In Vietnam, many enterprises have boldly invested in technology, expanded production, and reached international markets. This article compiles the Top 10 leading medical glove manufacturers trusted by customers at home and abroad. Table of..

Rubber is one of the most valuable and important materials in the medical field. From protective gloves to complex surgical instruments, rubber is used to manufacture a wide range of medical devices, helping improve the quality of care and protect public health. Below, Thai Duong Plastics explains the key applications of rubber in healthcare. Table..

Rubber is one of the most flexible and widely used materials in modern life, helping improve quality of life while ensuring safety, convenience, and sustainability across living spaces. In the article below, Thai Duong Plastics explains the importance and common applications of rubber in contemporary daily life. Table of Contents The importance of rubber materials..

Rubber is a vital industrial material thanks to its flexibility, elasticity, wear resistance, and good electrical insulation. In modern manufacturing environments, rubber is not merely supportive but a core component in many engineering systems. In this article, Thai Duong Plastics presents 11 representative and highly practical industrial applications of rubber today. Table of Contents Vibration..

Rubber is one of the most important materials in the modern automotive industry. Thanks to its superior technical characteristics, rubber is used widely across most vehicle components, helping boost performance, ensure safety, and extend service life. In the article below, Thai Duong Plastics explains in detail the role and applications of rubber in automobiles. Table..

Viton rubber is among the most widely used materials for applications that demand high durability and stability. In Vietnam, Viton is increasingly adopted in technical products supplied and fabricated by businesses-especially in rubber injection molding and seal manufacturing. Join Thai Duong Plastics to explore this rubber in more detail below. Table of Contents What is..

Butyl rubber, also known as isobutylene–isoprene rubber (IIR), is a synthetic material with a distinctive molecular structure. IIR is produced through the copolymerization of isobutylene (the main component) with a small amount of isoprene (typically below 5%). Owing to its very low degree of unsaturation, this polymer stands out for its exceptional gas impermeability, strong..

HNBR rubber was developed to address the limitations of NBR in harsh working environments. In this article, Thai Duong Plastics analyzes the technical characteristics, advantages, and applications of HNBR to help businesses choose a material solution suited to their production needs. Table of Contents Overview of HNBR rubber HNBR (Hydrogenated Nitrile Butadiene Rubber) is a..

CR rubber, also known as Neoprene, is a synthetic material noted for its high stability and outstanding environmental resistance. In this article, Thai Duong Plastics will help you better understand the characteristics, applications, and the most common forms of this rubber. Table of Contents What is CR rubber? CR stands for Chloroprene Rubber, synthesized through..

SBR (Styrene-Butadiene Rubber) is a synthetic rubber produced by the copolymerization of two main monomers: styrene and butadiene. It is one of the most widely used materials among synthetic rubbers today-especially in tire manufacturing and engineering rubber products-thanks to its good mechanical strength, high abrasion resistance, and stability across diverse environmental conditions. Table of Contents..

Vietnam is currently one of the world’s largest exporters of NR rubber. With more than 800,000 hectares of rubber plantations, annual latex output exceeds 1 million tons. Natural rubber is not only an essential raw material for domestic industries but also a leading export in the industrial agriculture sector. The following article from Thai Duong..

- 1

- 2