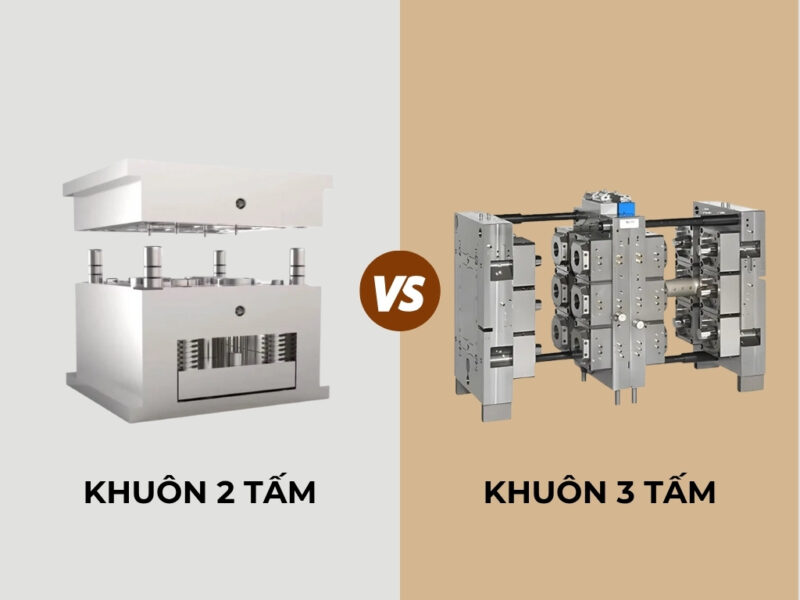

Molds play a decisive role in product quality and productivity in industrial injection molding. Among them, two-plate and three-plate injection molds are the two most widely used types. Although both are used to shape plastic parts, differences in design and operation mean each type suits different production needs.

Structural Differences Between Two-Plate and Three-Plate Molds

A two-plate mold has a simple structure consisting of two main halves: the fixed half (cavity side) and the moving half (core side), with a single parting line. When the mold opens, both the part and the runner are ejected together. This mold is easy to build and maintain, and it’s often used for products with modest aesthetic requirements.

A three-plate mold includes three sections: the fixed half, the moving half, and an intermediate (runner) plate. Thanks to this additional plate, gates can be placed more flexibly and part removal is more convenient-particularly suitable for multi-cavity parts or those requiring a superior surface finish.

Operating Principles of Two-Plate vs. Three-Plate Molds

Both types inject molten plastic into the cavity, cool, and solidify the part. The key difference lies in opening and part removal:

Two-plate mold

- Step 1: Molten plastic from the injection machine flows through the sprue bushing and runners, then fills the cavity to the part’s shape.

- Step 2: After the part cools and solidifies, the mold opens. The part and runner, still connected, are ejected together.

- Step 3: Once removed, the operator or a robot trims off the runner before the next process.

Three-plate mold

- Step 1: Molten plastic flows through the sprue bushing and runner system, then completely fills the cavities as designed.

- Step 2: When cooling is complete and the mold opens, the intermediate plate moves to create two separate openings: one for part removal and another for separating the runner from the part.

- Step 3: The runner and part are automatically separated. This eliminates manual trimming, saves time, and helps ensure a high-quality part surface.

So which mold should you choose for injection molding?

Both two-plate and three-plate molds deliver clear benefits in plastic production. A two-plate mold is typically the economical choice for simple designs with moderate complexity and medium output. Common items such as caps, boxes, household accessories, and some small technical parts are often made with two-plate molds because they are quick to manufacture, easy to maintain, and meet basic quality needs.

Conversely, three-plate molds are better for products requiring higher aesthetics, multiple cavities, or precise gate placement. With automatic runner separation and more uniform part surfaces, three-plate molds are often used for large-scale production, especially in electronics, medical, and engineering plastics.

Factors to Consider When Designing Two-Plate and Three-Plate Molds

Beyond structure and operating principle, consider these technical factors when choosing a mold type:

- Material type: Engineering plastics or parts needing very smooth surfaces often suit three-plate molds. For common commodity plastics, two-plate molds are cost-effective.

- Part complexity: Simple parts with fewer cavities favor two-plate molds. Multi-cavity parts or those needing flexible gate locations suit three-plate molds.

- Production volume: Two-plate molds are common for small to medium runs. Three-plate molds are preferable for mass production with high consistency.

- Investment cost: Two-plate molds cost less to build-ideal for limited budgets. Three-plate molds cost more upfront but can reduce operating and labor costs in mass production, improving long-term economics.

Comparison Table: Pros and Cons of Two-Plate vs. Three-Plate Molds

The table below summarizes the strengths and limitations of each mold type for easier evaluation:

| Criteria | Two-plate mold | Three-plate mold |

| Structure | Two plates; simple design with fewer components | Three plates; more complex construction |

| Manufacturing | Easier to machine; shorter lead time | Requires higher precision and more complex machining |

| Runner handling | Part and runner ejected together; manual trimming needed | Runner separates automatically on mold opening |

| Material usage | Short runner; less material waste | Longer runner; more material waste |

| Part aesthetics | Gate vestige may be visible | Better surface finish |

| Applications | Simpler parts; small to medium volumes | More complex parts; high-volume production |

You should weigh part characteristics, production scale, and budget to choose the optimal two-plate or three-plate injection mold-balancing both quality and cost. For detailed advice on plastic mold manufacturing for your specific product, please contact Thái Dương Plastics for support.

See also: The most common types of injection molds