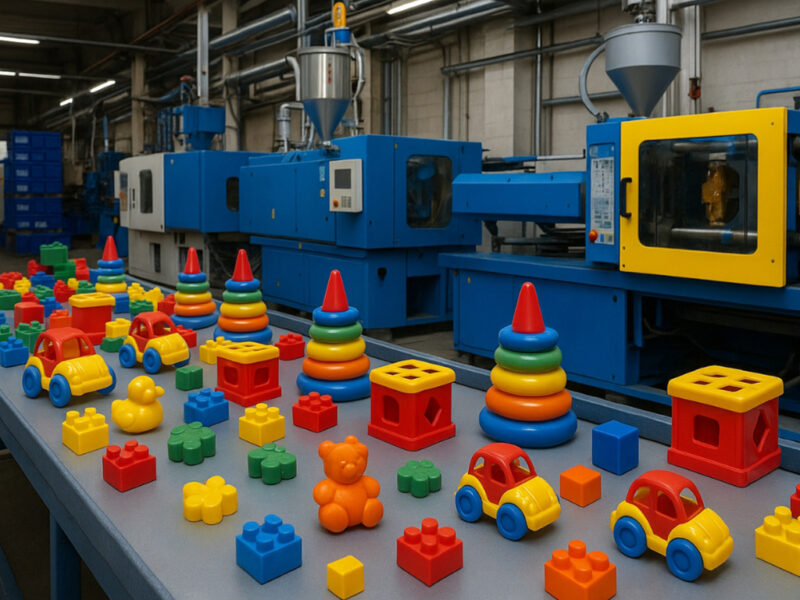

Plastic toys consistently rank among the best-selling product categories thanks to their diverse designs, reasonable prices, and ability to be mass-produced. To ensure consistent quality and on-time delivery, many businesses choose to partner with contract manufacturers rather than investing in machinery themselves. In this article, Thai Duong Plastics shares information about materials, technologies, and quality-control procedures in plastic processing for children’s toys, helping companies create products that are safe, durable, aesthetically pleasing, and cost-optimized.

Criteria for manufacturing children’s plastic toys

Safety is the top priority in toy production. Materials must be virgin resin, free from hazardous additives, and certified compliant with international standards such as EN 71 and ASTM F963. In terms of design, products should avoid sharp edges, limit small detachable parts for age groups under three, and feature smooth, non-flaking surfaces. In addition, clear labeling of age grades, instructions for use, and production lot codes enhances transparency and facilitates traceability.

Common plastic materials

Depending on the product line, manufacturers select suitable resins:

- PP (Polypropylene): Safe, heat-resistant, lightweight; often used for flexible parts such as trays, lids, and living hinges.

- ABS: Rigid with a glossy surface; holds screws well; suitable for models, building blocks, toy car bodies, and robots.

- HDPE: Excellent impact and weather resistance; commonly used for active-play products and outdoor toys.

- TPE or TPR: Soft and elastic; used for teething rings, low-noise wheels, grips, and other soft components.

- PC or PC blends: Tough and transparent; ideal when internal components need to be visible and crack resistance is required.

- Color masterbatches and printing inks: Must be child-safe, colorfast, and resistant to chipping.

Manufacturing technologies for children’s plastic toys

Depending on product characteristics, factories can combine multiple processes to achieve optimal quality and cost:

- Injection molding: Suitable for high-precision parts such as building blocks, model shells, wheels, and joints. Shrinkage must be calculated per material; proper draft angles and gate placement help minimize weld lines.

- Extrusion with cut-to-length profiling: Used to produce tubes, rods, and plastic filaments for tent kits or connector frames.

- Elastomer molding: Applied to TPE, TPR, etc., to form soft parts like hand loops and shock-absorbing pads.

- 3D printing and CNC prototyping: Rapid prototyping to verify dimensions and functionality before investing in steel tooling.

- Blow molding: For hollow products such as inflatable balls and toy bottles.

Molds must be carefully engineered to ensure quality. Standard molds are typically made from P20 or H13 steel, with reinforcing ribs and well-designed cooling systems to reduce defects and extend service life. For products with multiple variants, insert-style molds are often used to switch details quickly and save costs.

Reliable, cost-effective contractor for children’s plastic toys

Thai Duong Plastics undertakes a wide range of children’s toy products to serve diverse needs:

- Educational building sets and models: Interlocking bricks, tracks, vehicle/train models-supporting cognitive development and creativity.

- Battery-operated technical toys: RC cars, robots, toy instruments-manufactured to electrical safety standards.

- Active-play toys: Plastic balls, seesaws, flying discs, and mini sports gear-promoting physical exercise.

- Pretend-play sets: Doctor’s kits, cooking sets, and role-play accessories-rounded designs that are easy to hold.

- Soft accessories for toddlers: Teething rings, cushioned wheels, and components made from safe TPE.

Every project begins with an in-depth consultation to understand the customer’s requirements. After alignment, our engineering team prepares drawings, makes prototypes, fabricates molds, and proceeds to mass production. Before delivery, finished goods undergo stringent inspection and are packaged on schedule.

Quality control procedures

We implement a closed-loop quality-control system to keep products consistent and shorten time-to-market:

- Sample approval and mold trials: Verify fit, clearances, actuation force, and baseline durability.

- Physical and mechanical testing: Drop tests, weld-line tensile checks, small-parts evaluation by age group, and adhesion testing of printed layers.

- Color control: Visual matching to master samples and instrument-based color measurement.

- Chemical testing: Representative samples sent to accredited laboratories for standard compliance evaluation.

- Traceability: Recording material codes, production orders, operating shifts, and molding parameters to enable rapid response to feedback.

Thai Duong Plastics is committed to optimizing costs while guaranteeing quality and schedules for every children’s plastic toy order. We partner with you from design and mold making through production and after-sales support, delivering internationally compliant, safe, and effective products for your business.

Reference: Industrial plastic injection molding capability at Thai Duong Plastics