PP plastic is one of the most commonly used plastics in injection molding thanks to its outstanding advantages. In the article below, Thai Duong Plastics provides an in-depth analysis of the structure, characteristics, pros and cons, and potential applications of PP to give you a comprehensive view of this versatile material.

What is PP (Polypropylene)?

Polypropylene is a polymer obtained from the polymerization of the monomer propylene (C3H6). On the molecular level, PP has a repeating structure of (C3H6)n and belongs to the group of semi-crystalline thermoplastics. It is colorless, odorless, tasteless, highly pure, and fully recyclable, meeting safety standards for both industrial and food-related applications.

The molecular structure of PP can be arranged in three stereoregular configurations: isotactic, syndiotactic, and atactic. Among them, isotactic PP has the highest crystallinity, superior mechanical properties, and is the most commonly used type in industrial manufacturing.

Key Properties

PP plastic offers a combination of outstanding physical, chemical, and mechanical properties:

- Specific gravity: approx. 0.90–0.91 g/cm³

- Melting temperature: 160–170°C, ideal for thermal processing

- Young’s modulus: 1.5–2 GPa

- Tensile strength: approx. 30–40 N/mm²

- Elongation at break: up to 700%, depending on the polymer grade

- High dielectric strength: 30–32 kV/mm

- Chemical resistance: withstands dilute acids, bases, oils, and most organic solvents

- Excellent barrier properties against gases and moisture, maintaining mechanical strength under changing environmental conditions

In terms of mechanics, PP is stiffer than PE and retains its shape well after bending or mild torsion. However, it tends to degrade under long-term UV exposure without stabilizing additives.

Common Types

PP plastics on the market are generally divided into two main groups based on polymer structure.

Homopolymer PP

The standard type with high rigidity and good dimensional stability. Ideal for products that require structural strength, such as technical components, mechanical boxes, and furniture parts.

Copolymer PP

Includes two primary variants:

- Block copolymer: Contains 5–15% ethylene to improve impact resistance. Suitable for technical parts in automotive, electronics, etc.

- Random copolymer: Randomly polymerized from propylene and a small amount of ethylene (1–7%). Offers higher flexibility and transparency. Commonly used in packaging, household appliances, and medical products.

Advantages and Limitations of Polypropylene

PP plastic is widely used thanks to its superior mechanical, thermal, and chemical properties:

- Low production cost and easy to process on automated production lines

- Low density helps reduce product weight

- High stiffness and tensile strength, suitable for light-load components

- Excellent chemical resistance, inert to many common solvents

- Effective electrical insulation and stable under moisture or high electrical fields

- Moisture- and oil-resistant; maintains long-term stability and can be recycled multiple times without significant property loss

- Glossy surface, easy to clean, and dirt-resistant

However, PP also has some technical drawbacks worth noting. It has a high thermal expansion coefficient and may deform under large temperature fluctuations. PP is not inherently UV resistant and can age without protective additives. The surface is difficult to paint or print on without pretreatment. It is flammable, oxidizes at high temperatures, and is not resistant to chlorinated or aromatic solvents. It also has low transparency and often appears milky-white.

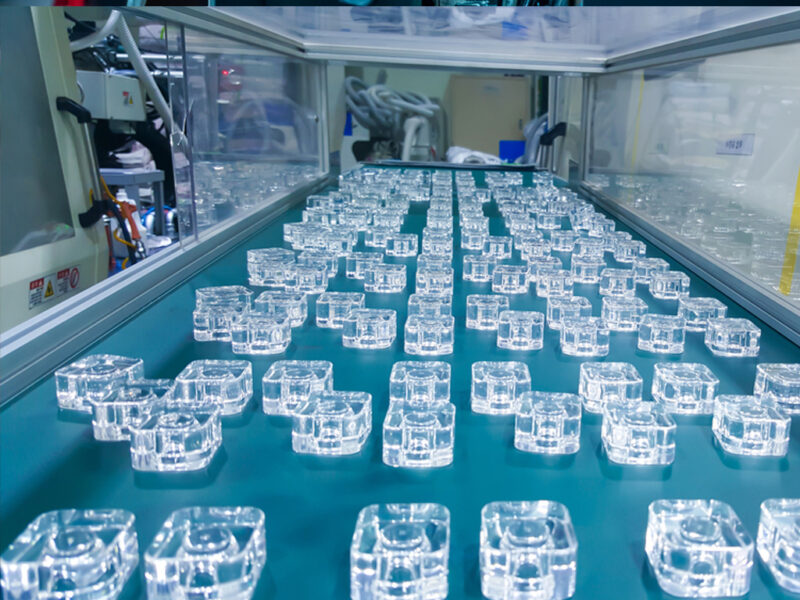

Applications of PP in Injection Molding

In plastic injection molding technology, PP is widely used to produce complex-shaped parts such as:

- Housings for electrical and electronic devices, control panels, handles

- Components in water purifiers, rice cookers, and household appliances

- Automotive and motorcycle parts, engine covers, spoilers

- Food packaging: plastic boxes, screw caps, disposable cutlery

- Medical devices: syringes, baby bottles, pharmaceutical containers

Beyond injection molding, PP is also used in:

- Extrusion of water pipes, insulating liners, technical belts

- Film production using BOPP (biaxially oriented polypropylene) for packaging and food storage

- Woven PP fibers for packaging sacks, cement bags, and agricultural containers

Is PP Plastic Safe?

PP plastic is considered safe for both human health and the environment. It contains no BPA, does not emit toxic fumes under normal processing temperatures, and has resin code 5, indicating high recyclability. PP is widely used in products that come into direct contact with food, children’s items, and medical devices, as it meets strict hygiene and biocompatibility standards.

PP is a semi-crystalline thermoplastic with high applicability in modern industry thanks to its processability, mechanical strength, and cost-effectiveness. With the outstanding features mentioned above, PP is regarded as an optimal solution for technical, consumer, and packaging products in a production environment that prioritizes sustainability and economic efficiency.

See also: Current development status of the plastic molding industry in Vietnam