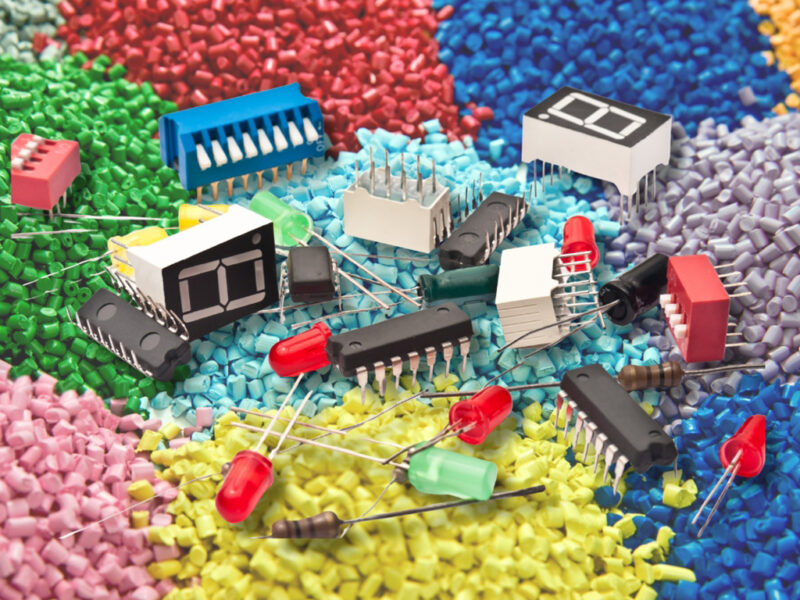

Plastic component manufacturing is the process of producing plastic parts according to technical drawings, serving a wide range of industries such as mechanical engineering, electronics, automotive, and healthcare. With advantages in light weight, durability, formability, and cost-effectiveness, plastics are increasingly used to replace metals in many applications. This process demands modern technology and high precision to ensure products meet technical specifications and deliver long-term durability in use.

Common methods for manufacturing plastic components

To produce high-quality plastic components for machinery, manufacturers typically apply multiple methods. Each has its own strengths and is suited to specific products and production requirements. Choosing the right technique helps ensure accuracy, durability, and optimized cost:

- Injection molding: The most common method in plastic component manufacturing. It enables mass production of parts such as electrical housings, switch frames, plastic gears, automotive components, and industrial machine parts-with high precision.

- Blow molding: Less often used directly for machine components, but applied to create hollow technical parts like tubing, plastic reservoirs, and other auxiliary items integrated into production systems.

- CNC machining: Typically used for low-volume orders or prototyping. CNC allows precise material removal from plastic stock, suitable for technical parts such as couplings, support plates, and insulating components.

- Compression molding: Uses heat and pressure to press plastic into a mold; commonly applied to load-bearing technical parts such as protective covers for industrial equipment and insulating panels.

Plastics used in manufacturing machine components

Selecting suitable plastic materials has a major impact on product quality and service life. Common options include:

- PC (polycarbonate) offers high strength and transparency; widely used in electronics and protective lenses.

- POM (acetal) provides excellent wear resistance and low friction; often used for shafts and gears.

- PP (polypropylene) has good heat resistance and chemical resistance; suitable for components in medical and food applications.

- ABS features high toughness and impact resistance; used for parts requiring rigidity and mechanical stability.

Steps in manufacturing plastic components

A high-quality plastic product typically follows a standardized, multi-step workflow:

- Step 1: Receive customer drawings or design concepts.

- Step 2: Select the plastic material to match technical requirements and operating environment.

- Step 3: Create a 3D model using CAD/CAM software for verification and simulation.

- Step 4: Form the component via injection molding, blow molding, compression molding, or CNC machining.

- Step 5: Inspect quality against dimensional, strength, and precision standards.

- Step 6: Package the finished product and deliver to the customer.

When implementing a project, businesses should provide clear drawings and technical specifications to avoid production errors. Regular communication with the manufacturer helps identify the most suitable process, reduce costs, and shorten time to completion.

Criteria for choosing a plastic component manufacturer

Selecting the right partner is crucial to product success. Consider the following criteria:

- Experience and craftsmanship to handle complex technical requirements.

- Modern machinery to ensure high precision and stable production.

- Product quality that meets standards for durability and service life.

- Customer support from design and material selection through after-sales service.

- Reasonable pricing that balances cost and quality to optimize budgets.

Reputable provider of plastic component manufacturing

Outsourcing plastic component manufacturing offers tangible benefits: reduced capital expenditure on equipment, shorter production timelines, and consistent product quality. For large orders, customers may also receive favorable tooling and production pricing.

With years of experience and modern facilities, Thai Duong Plastics has become a trusted partner for many clients in plastic component manufacturing. The company commits to producing exactly to technical drawings and works closely with customers throughout production and use.

With competitive pricing and flexible policies, Thai Duong Plastics is a reliable choice for businesses that need precision manufacturing of plastic machine components. Please contact Thai Duong Plastics for detailed consultation, technical support, and a suitable quotation.

Information: Industrial injection molding capabilities at Thai Duong Plastics