Rotational molding (also called rotational moulding or rotomolding) is a plastics-processing technology that is less common than injection or blow molding. It is an optimal process for large, hollow products that require high mechanical strength. In this article, Thai Duong Plastics explains what rotomolding is and how it differs from thermoforming, helping you choose the most suitable manufacturing technique.

What is rotational molding?

Rotational molding is a process in which finely ground plastic powder or pellets are loaded into a mold. The mold is then heated and rotated continuously around two perpendicular axes. Under heat and rotation, the molten plastic coats the mold surface uniformly, creating a seamless, hollow part with no weld lines. The process runs at low pressure, making it ideal for large, complex products that are difficult to achieve with other methods.

Materials used in rotational molding

Unlike injection molding, which uses pellets, rotomolding uses plastic powder to ensure complete melting and even coverage:

- Polyethylene (PE): Accounts for over 80% thanks to its impact strength, UV resistance, and reasonable cost.

- Polypropylene (PP): Stiffer with better heat resistance.

- PVC: Used for flexible products.

- Nylon (PA), Polycarbonate (PC): For higher-performance applications requiring heat and strength.

Additives can be incorporated for flame retardancy, antistatic performance, weatherability, and food-contact safety.

Advantages and limitations of rotomolding

Rotational molding offers notable benefits:

- Capable of producing large, hollow, robust structures.

- Lower tooling cost than injection or blow molding.

- Uniform wall thickness with excellent impact resistance.

- Minimal scrap; excess material can often be reused.

- Flexible in color, size, and design-changes are relatively easy to implement.

There are also limitations:

- Long cycle times (due to heating and cooling), resulting in lower throughput.

- Lower precision on small, sharp details than injection molding-fine threads or intricate textures are difficult.

- Material choices are more limited, with polyethylene being predominant.

Rotational molding vs. thermoforming

The differences below can help you select the right technology for your product:

| Comparison of Rotational Molding and Thermoforming | |||

| No. | Criteria | Rotational molding | Thermoforming |

| 1 | Principle | Plastic powder melts and coats the inside of a rotating mold | A heated plastic sheet is vacuum-formed or pressure-formed over a mold |

| 2 | Suitable products | Large, hollow, robust parts; small-to-medium volumes (tanks, kayaks, fuel tanks, buoys…) | Thin-walled parts; high-volume production (trays, containers, panels, housings, cladding…) |

| 3 | Wall thickness | Uniform; naturally reinforced at corners/edges | Non-uniform; walls thin significantly in deep-draw areas |

| 4 | Tooling cost | Low-well-suited to small/medium runs | Medium to high-optimized for mass production |

| 5 | Production cycle | Long-about 1–2 parts/hour | Fast-supports large quantities |

| 6 | Common materials | PE, PP, PVC, PA, PC | ABS, HIPS, PET, PVC, PMMA, PC |

| 7 | Detail precision | Moderate; fine threads and sharp micro-details are not feasible | Higher; crisp detail in regions contacting the mold |

Rotational molding process

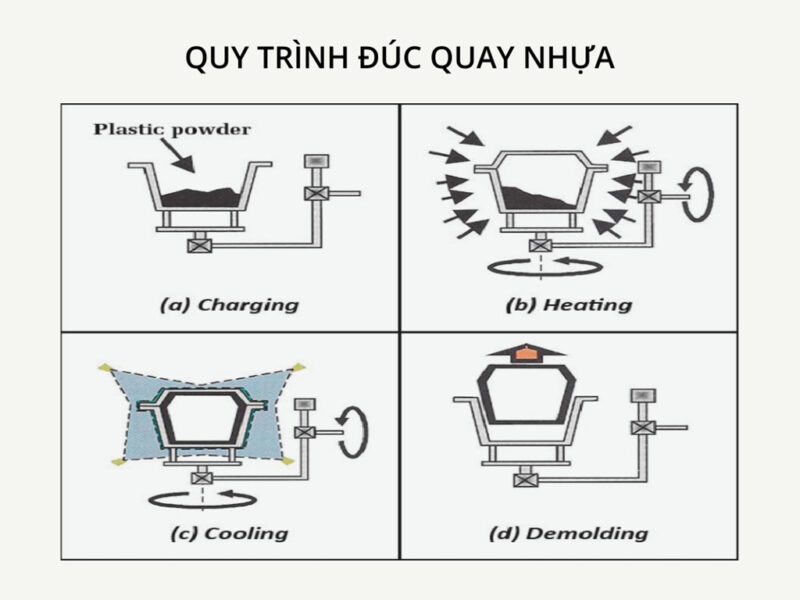

The process comprises four basic stages:

Step 1: Charging the material

Plastic-typically polyethylene powder-is precisely metered (shot weight) before being loaded into the mold. The powder is poured directly into the hollow mold; uniform distribution occurs during rotation as the mold heats.

Step 2: Heating and mold rotation

The charged mold is placed in an oven and rotated continuously about two perpendicular axes at low speed. The plastic melts and, under rotation, coats the entire mold surface to form a seamless part with even wall thickness.

Step 3: Cooling

The mold is removed from the oven and cooled with air or water mist. As temperature drops, the plastic solidifies and shrinks slightly. Cooling rate control is critical: overly rapid cooling can cause warpage or cracking.

Step 4: Demolding and finishing

Once solidified, the mold is opened and the part is removed. Only minor finishing-such as trimming flash, fitting inserts, or printing a logo-is usually required before use.

Design tips for rotationally molded products

To achieve high-quality results, designers should consider:

- Use generous radii to promote uniform coverage and prevent thin walls at sharp corners.

- Provide draft of at least 1° on exterior surfaces and 3–5° on interior/deep features to aid demolding.

- Maintain adequate spacing between parallel walls (at least 3× wall thickness) to avoid webbing and poor flow.

- Metal inserts or foam can be added during molding to increase strength, create robust threads, or add insulation.

Real-world applications of rotational molding

Below are representative sectors that benefit from rotomolding:

- Agriculture

Rotomolding is used to produce water tanks, fertilizer/chemical containers, and seed silos-products requiring high durability, corrosion resistance, and outdoor weatherability.

- Marine

Lifebuoys, mooring buoys, kayaks, and rescue boats are commonly rotomolded because seamless, hollow parts are lightweight, buoyant, and resistant to the marine environment.

- Industry and manufacturing

This technology produces fuel tanks, chemical tanks, and specialized containers with high strength, minimal leakage, and safe handling during transport.

- Transportation and urban infrastructure

Traffic cones, barriers, and public waste bins are rotomolded-lightweight, durable, easy to replace, and weather-resistant.

- Consumer goods

Rotomolding enables diverse products such as toys, coolers, planters, and decorative items, often with aesthetic requirements and integrated logos or textures directly in production.

We hope this article clarifies the process and applications of rotational molding, as well as its differences from other manufacturing methods. If you need more detailed advice or an optimal industrial injection molding solution, please contact Thai Duong Plastics for support.