Plastic processing refers to the transformation of thermoplastic or thermosetting resin pellets into finished products based on technical drawings. With the integration of robotics, AI sensors, CAD/CAM software, and 3D measurement systems, this service is now widely present in the supply chains of automotive, electronics, medical, packaging, and consumer goods industries. In this article, Thái Dương Plastics introduces the definition, benefits, technologies, processes, and latest trends in plastic processing.

Overview of Plastic Processing

Definition of Plastic Processing

Plastic processing encompasses a set of techniques that use heat, pressure, or cutting force to transform raw plastics (ABS, PP, PVC, PET, HDPE, PC, POM…) into components with the desired size, shape, and features that match technical drawings. The six main processing technologies include:

- Injection Molding

- Blow Molding

- Extrusion

- CNC Machining

- Rotational Molding

- Vacuum Casting & 3D Printing

Each method is suited to specific part geometries, production volumes, and mold budgets, enabling businesses to flexibly select the optimal solution.

Key Benefits of Plastic Processing

- 30–50% cost savings compared to metal processing due to lower material density, reduced waste, and shorter production cycles.

- Customizable design: Plastics easily accommodate ribs, hidden threads, snap fits, and support design-for-manufacturing; colors and additives can be blended directly into pellets.

- Short time-to-market: Injection molding cycles of 5–30s per part reduce prototyping and mass production timelines.

- Lightweight components reduce logistics costs and improve performance of handheld devices and automotive parts.

- Functional additives (antibacterial, UV-resistant, flame retardant) can be integrated during compounding, eliminating the need for post-coating.

- Support for sustainable development: Many factories now use rPET, rPP, or biopolymer PLA, meeting ESG and ISO 14001 standards.

Comparison of Common Methods

| Method | Principle | Advantages | Typical Products |

| Injection Molding | Molten plastic is injected into steel molds under 80–200 MPa, cooled, then ejected | ±0.05 mm precision, ideal for high-volume, complex parts | Phone casings, auto parts, container lids |

| Blow Molding | Hot parison is inflated at 0.6–1.0 MPa to form hollow shapes | Seamless, lightweight, high-speed | PET bottles, 20L containers, hollow toys |

| Extrusion | Molten plastic is continuously pushed through a fixed-profile die | Low cost, continuous production | PVC pipes, PP sheets, decorative trims |

| CNC Machining | 4–5 axis milling/turning machines cut plastic blocks based on G-code | ±0.02 mm tolerance, no mold required, ideal for prototypes | Jigs, technical housings, POM, PMMA parts |

| Rotational Molding | Powdered LLDPE evenly coats mold interior via multi-axis rotation | Large hollow parts, uniform thickness, no weld lines | Water tanks, industrial bins |

Standard Plastic Processing Workflow

The plastic molding process involves multiple stages, combining engineering, technology, and quality control.

Product & Mold Design

- Create 3D models using SolidWorks, AutoCAD, Creo, or Fusion 360.

- Run Moldflow simulations to optimize gating, cooling, and mold separation mechanisms.

- Calculate melt flow, mold strength, and lifespan to ensure stable production.

Material Selection & Preprocessing

- Common materials: ABS (rigid, impact-resistant), PP (lightweight, chemical-resistant), PVC (insulating, flame-retardant), PC (transparent, strong), POM/PA/HDPE (precision mechanics).

- Dry at 80–120°C before processing to prevent bubbles or defects.

Shaping the Product

- Choose technology based on shape and volume:

- Injection molding: complex parts, mass production.

- Blow molding: bottles, hollow containers.

- Extrusion: pipes, sheets, continuous profiles.

- CNC machining: prototypes, high precision.

- 3D printing: rapid prototyping, custom designs.

- Servo injection machines, twin-screw extruders, and 4–5 axis CNCs ensure speed and low deviation.

Cooling & Product Removal

- Water/air cooling stabilizes dimensions.

- Robotic pickers minimize breakage, misalignment, and increase productivity.

Quality Control (QC)

- Inspect dimensions, thickness, gloss, color, and mechanical properties using CMMs, calipers, UV boxes, and tensile testers.

- Only compliant products proceed to the next stage.

Finishing & Packaging

- Trim flash, polish, paint, print logos, or apply laser marking.

- Conduct trial assembly, then pack according to transport standards.

This closed-loop workflow ensures plastic products meet tight tolerances, aesthetics, and cost-efficiency. Partnering with a processor equipped with modern technology and strict QC systems is key to accelerating market launch and enhancing competitiveness.

Popular Plastic Processing Technologies Today

Each modern plastic processing method has unique technical features suitable for specific products, volumes, and precision requirements. Below are the most commonly applied technologies:

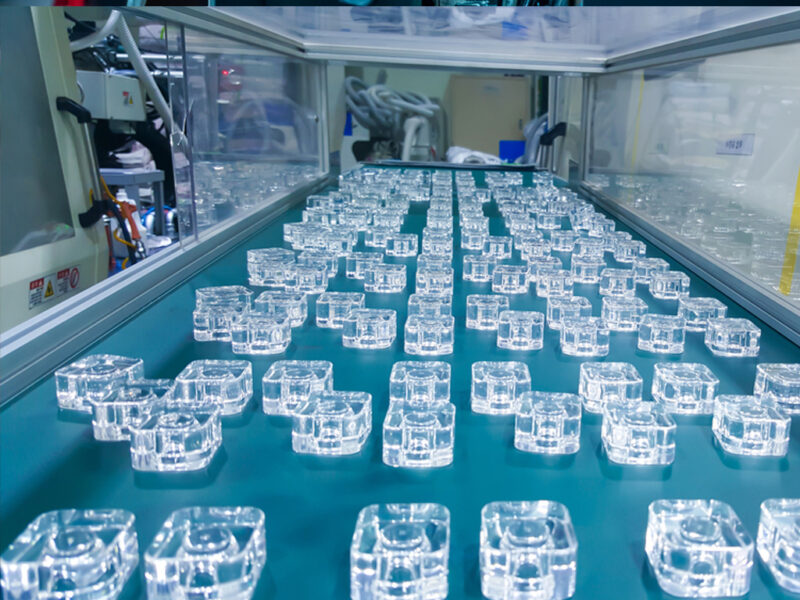

Injection Molding

- Principle: Plastic pellets are plasticized, injected into sealed steel molds, and water cooling channels maintain cycles under 15 seconds.

- Advantages: Complex geometries, tight tolerances, high productivity; supports over-molding and in-mold labeling.

- Applications: Laptop shells, handles, battery trays, precision mechanical parts.

Learn more: Common types of plastics used in injection molding

Blow Molding

- Principle: Tube-shaped parison is clamped in a mold and inflated to form hollow parts.

- Advantages: Seamless, lightweight, high-speed production.

- Applications: Beverage bottles, chemical drums, automotive fuel tanks.

Extrusion

- Principle: Thermoplastics are melted and pushed through a constant-profile die, then cooled by water or air.

- Advantages: Low cost, continuous output, minimal scrap.

- Applications: Water pipes, plastic boards, packaging films.

CNC Plastic Machining

- Principle: CNC-controlled milling/turning machines cut plastic blocks or sheets based on CAD → CAM drawings.

- Advantages: ±0.02 mm accuracy, no mold needed, suitable for high-mix low-volume runs.

- Applications: Jigs, prototype molds, medical device housings, PEEK and PEI components.

Rotational Molding

- Principle: Hollow molds filled with LLDPE powder rotate on multiple axes, evenly distributing molten plastic across the mold walls.

- Advantages: Large hollow parts (≤10m), uniform wall thickness, no welds.

- Applications: Water tanks, garbage bins, life buoys, garden toys.

See also: Detailed classification and structure of injection molds

Plastic processing offers significant advantages in cost, speed, and design flexibility. It is an ideal choice for businesses aiming for mass production or rapid product development. To achieve optimal results, partner with a reputable processor with advanced technology and a clearly defined quality process.

Thái Dương Plastics provides professional plastic injection services tailored to your needs, operated by experienced engineers using cutting-edge equipment—ensuring precision, durability, and cost efficiency across all industries.